Plastic CNC milling at a glance

- Process: 5-axis CNC machining for precise reworking of deep-drawn parts

- Advantages: maximum precision, edge-free trimming, complex 3D geometries

- Application: technical components, precise recesses

- Special feature: cost-efficient for variant production and small series

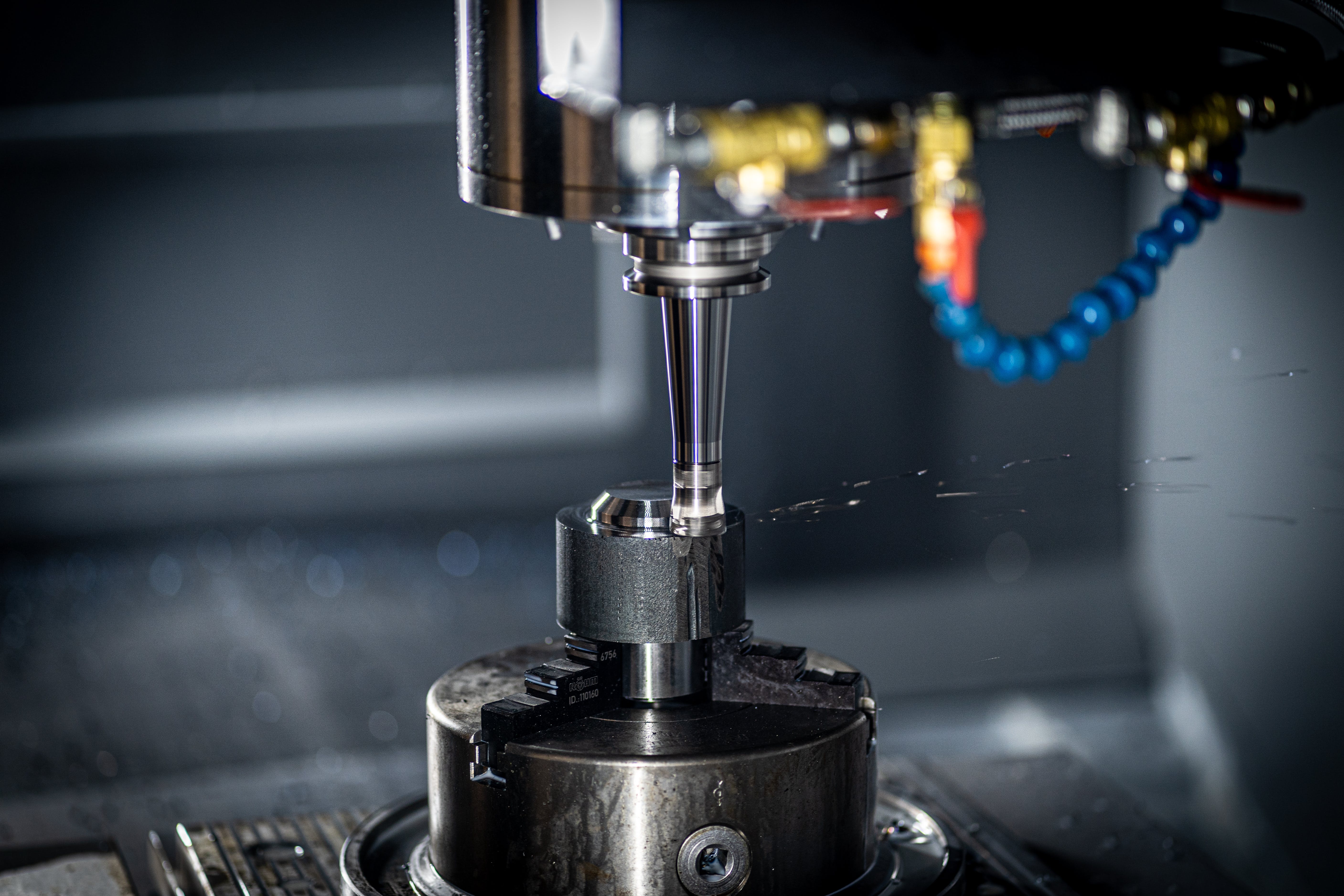

Plastic CNC Milling: 5-axis CNC Milling Machines

Cuts in complex dimensions can often only be realized with CNC plastic milling and a detailed milling line. After the forming process, the thermoformed part is clamped onto a milling device and trimmed with a multi-jointed robot arm. Thanks to the electronic CNC control system, several cuts can be made in succession. In addition, recesses and slots in various sizes and contours can be created during plastic CNC milling using tool changers, as well as three-dimensional cutting lines.

CNC Definition

CNC stands for Computerised Numerical Control. The milling machine is controlled by a computer, which enables particularly accurate and consistently precise CNC machining. Automation makes the milling process more precise and faster than would be possible with manual human labour.

Cutting speed

The optimum cutting speed determines the quality and efficiency of plastic CNC milling. Modern 5-axis milling machines with CAD/CAM control automatically adjust the feed rate and speed to the material and contour, ensuring fast, clean cuts without deformation.

Further advantages of plastic CNC milling

Dynamic development opportunities

With plastic CNC milling, changes can be implemented quickly by adjusting the programme and/or the milling head.

Early simulation

Simulation using CAD/CAM software allows weak points to be identified proactively and resolved in an application-oriented manner.

Complex cuts

Milling plastic is the only option for complex cuts. Three-dimensional cuts, recesses and slots for ventilation openings can only be achieved using a CNC milling machine.

Low cutting tool costs

CNC milling costs: The programme and device for the CNC milling machine are less expensive than a punching tool (even if the machining step itself is longer/more expensive).

Plastic CNC milling: properties and possibilities

| Properties and Technical Capabilities in Plastic CNC Milling | Specifications in Plastic CNC Milling |

|---|---|

| Cutting Edge | Clean cut. The edge can and should be additionally deburred. |

| Haptics of the Cutting Contour | Deburred edges result in a clean and smooth finish. |

| Optics of the Cutting Contour | High-quality appearance, especially due to the high reproducibility of the cut contour enabled by CNC control. |

| Max. Material Thickness for Cutting | No upper limit; suitable for thin-walled materials starting from ~0.5 mm wall thickness. |

| Maximum Processing Sizes | 3,000 x 2,000 x 560 mm |

| Edgeless Cutting | Easily possible. Plastic CNC milling is the only option for edgeless cuts in three-dimensional and more complex contours. |

| Adjustable Cutting | Easily achievable in CNC processing. Milling heads can be flexibly swapped during production via tool changer systems with various sizes. |

| Contours with Varying Heights | Three-dimensional cut lines are easily possible. |

| Cutting Speed in Plastic Milling | Speed selection also depends on the type of material. Impact-resistant plastics can generally be milled at higher speeds of up to 10 m/min. |

| Risk of Deformations (Burring or Hair-like Residue) | Very low risk if the workpiece is correctly clamped and the milling head and speed are appropriately chosen. |

| Durability | Low wear. However, the milling fixture should still be checked for damage after each production run. |

Process requirements for plastic CNC milling

- Heat dissipation via the chip: Milling generates heat, which is dissipated via the removed chips.

This prevents the component from deforming or melting locally. - Low thermal conductivity of the material: Plastics conduct heat much less efficiently than metals. Controlled cutting speeds and sharp tools are therefore crucial to prevent thermal damage to the cut edge.

- Quality assurance through correct clamping and tool selection: Precise clamping and the right milling head ensure dimensional accuracy, clean edges and an even surface.

Frequently asked questions about plastic CNC milling

CNC milling enables three-dimensional contours and edge-free cuts that cannot be achieved with strip steel cutting or shear cutting.

Other Cutting Processes besides Plastic CNC Milling

Would you like to know what other cutting processes are available for plastic thermoforming in addition to CNC milling? We provide you with all the necessary information on other processes - such as steel rule cutting and shear cutting, which are part of the punching process.