Plastic printing at a glance

- Process: Subsequent printing of thermoformed parts (off-mould decoration)

- Techniques: Screen printing for surfaces, pad printing for shapes

- Advantages: Colour brilliance, CI-compliant design, high durability

- Applications: Housings, bezels, trays, control panels, logos

When Should Plastic be Printed?

Printing on thermoformed parts belongs to the "off-mold decorations" category, meaning it is applied after the forming process. Due to the vast range of design and color options, printing is the ideal solution for intricate lettering, designs, branding, and corporate identity (CI) elements. Various printing techniques are used depending on the application area. You can print on plastic covers, trays, enclosures, and virtually anything thermoformed.

Advantages of printing on plastic

High degree of design freedom

Logos, lettering, technical markings or CI elements: plastic printing allows almost any design to be reproduced with precision.

Flexible application on moulded parts

Thanks to pad printing and screen printing, both flat surfaces and curved geometries can be printed without any problems.

High durability

Printed plastic parts are resistant to abrasion, chemicals and external influences.

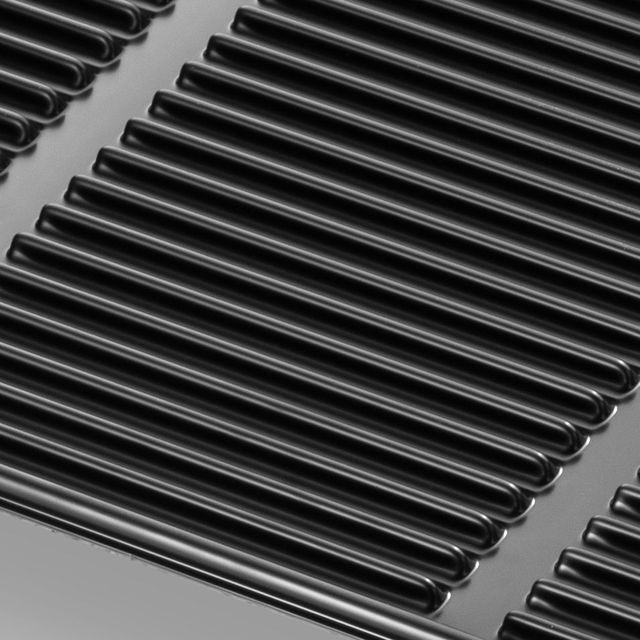

Printing on plastic using screen printing

The ink is pressed onto the plastic through a fine-mesh screen using a squeegee.

This process is particularly suitable for flat or slightly curved surfaces.

Advantages

- Very high colour coverage and brilliant colours

- Metallic or special colours possible

- Ideal for large-area motifs, logos or decorations

- High layer thickness ensures durable surfaces

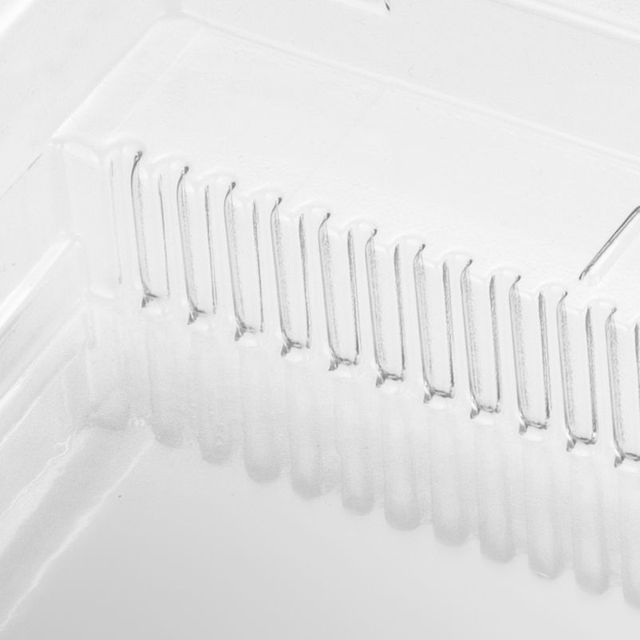

Which plastics can be printed on?

Printing on plastic parts is possible with a wide range of thermoplastics. It is important to note that not all plastics are equally suitable for printing. Some plastics naturally have lower surface tension, which can make it difficult for the printing inks to adhere. In such cases, it is advisable to carry out special pre-treatments such as cleaning, degreasing or the use of adhesion promoters in order to achieve better adhesion.

Frequently asked questions about printing on plastic

Pad printing is suitable for round or uneven surfaces, while screen printing is ideal for flat surfaces with a high ink layer thickness. Read more about this in our blog post Screen printing vs. pad printing.

Other Surface Treatment Methods

Looking for alternatives to plastic printing? We provide all the essential information on other finishing techniques.