An overview of painting plastic

- Process: Subsequent colouring and coating of thermoformed parts

- Materials: Ideal for ABS, PC, PMMA

- Colours: All RAL colours, metallic, effect and special colours possible

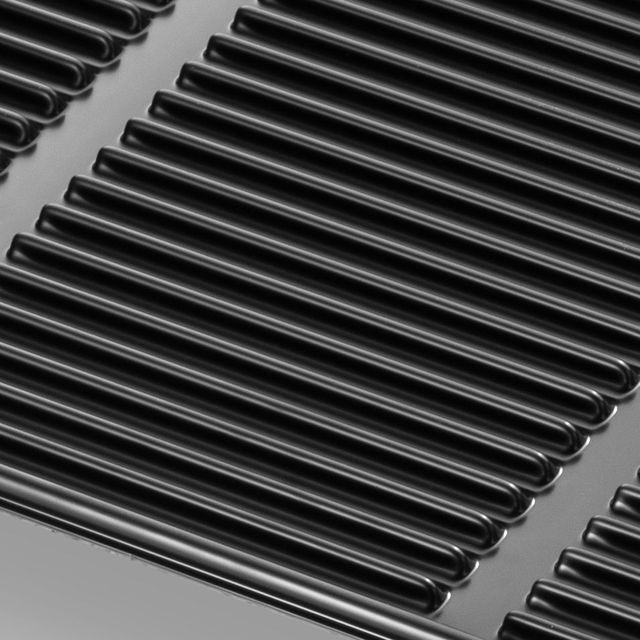

- Finish: High gloss, matt, textured

- Advantages: Individual colour design, scratch-resistant surfaces, flexible quantities

How Does Plastic Painting Work?

One of the advantages of thermoformed parts is that the base materials (semi-finished products) can be pre-colored in the desired shade. However, certain limitations in procurement must be considered. In some cases, the desired color can only be applied after the thermoforming process. This is where "off-mold decorations" come into play: thermoformed parts are painted after shaping. Below, we explain the benefits and possibilities of plastic painting.

When is Plastic Painting Necessary?

Minimum Order Quantities (MOQs)

Specific (RAL) color requirements may demand quantities that are too low to justify custom-colored material extrusion.

Special Effects with Plastic Painting

While base materials are typically pigmented before extrusion, special finishes—such as matte or high-gloss surfaces—must be applied later through painting.

Multicolored Plastic Parts

When different color zones are required on the same part, direct pre-colored extrusion is not an option, making plastic painting the ideal solution.

Which Plastics can be Painted?

Compared to metals, plastics have lower surface energy, which means that paints do not adhere equally well to all thermoplastics. The following are particularly suitable for plastic coatings:

Properties & advantages of painting plastic

Custom colour design

All RAL colours, metallic, effect or special colours are possible, even for small quantities.

Versatile surface options

Whether high gloss, matt or textured paint, any surface finish is possible.

Protection and durability

2K PUR polyurethane-based paints provide robust, scratch-resistant and chemical-resistant surfaces.

Design freedom

The surfaces of the thermoformed parts can be coloured over the entire surface or partially, and different colours are also possible.

Technical information on plastic coating

- 2K PUR lacquers are mainly used.

- Polyurethane lacquer (or polyurethane-reinforced lacquers) result in resistant and particularly durable surfaces.

- 2-in-1 products are capable of lacquering deep-drawn parts even without a separate primer.

- The surface must be cleaned before coating.

- Materials that are difficult to coat, such as PP and HD-PE, should be sanded beforehand and/or coated with a primer (adhesive).

Frequently asked questions about painting plastic

Two-component PUR paints based on polyurethane have proven particularly effective, as they offer high adhesion and resistance.

Other Surface Treatment Methods

Looking for alternatives to plastic painting? We provide all the necessary details on additional finishing techniques.