Strip steel cutting at a glance

- Process: Knife cutting with strip steel knife

- Typical application: Small and medium series, sample parts

- Cutting quality: Good contour, slight predetermined breaking points and retaining bars possible

- Advantages: Low tool costs, short set-up times, can be heated to 200 °C

- Restrictions: Limited service life, no edge-free punching

What is Band Steel Cutting?

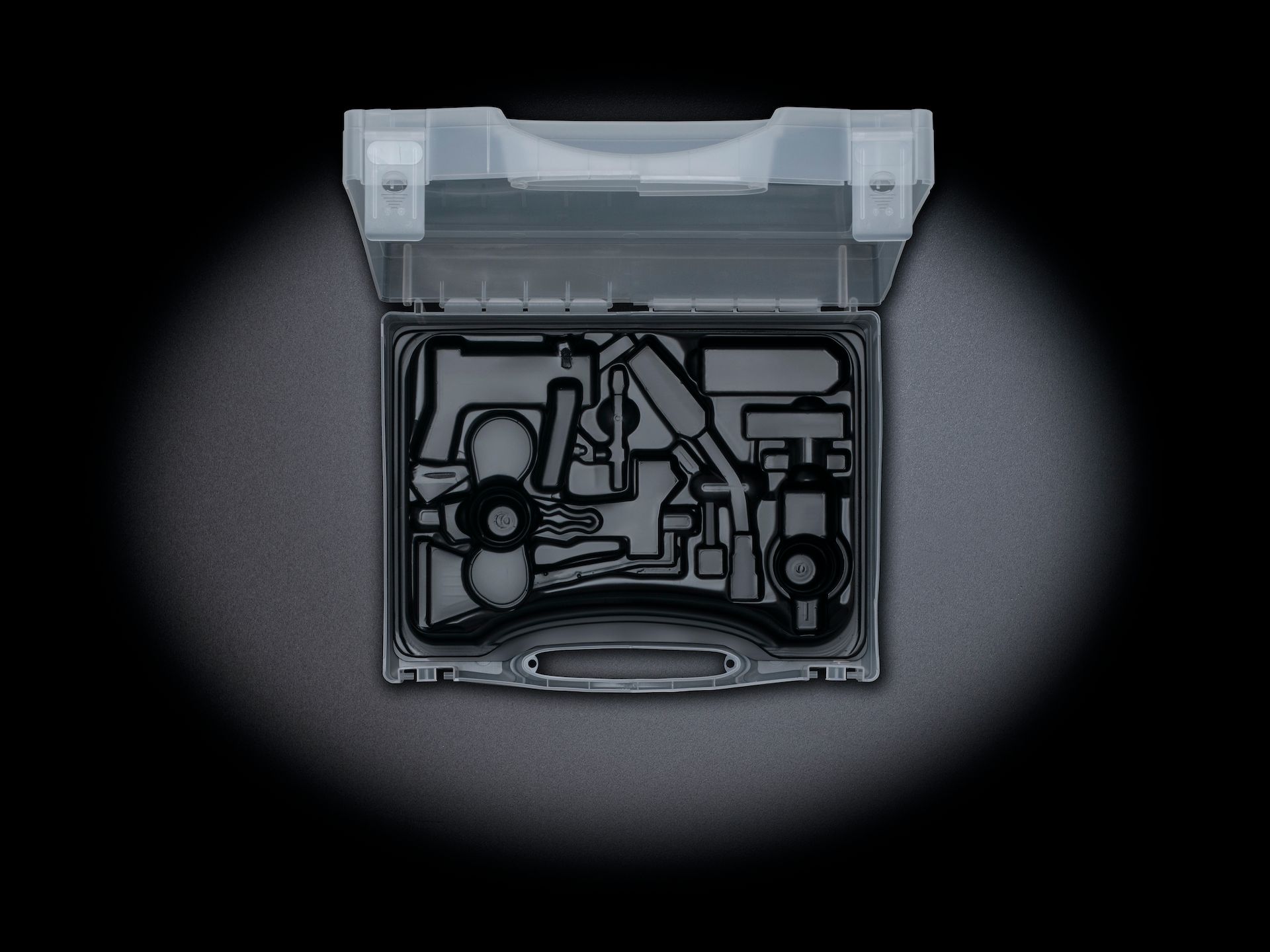

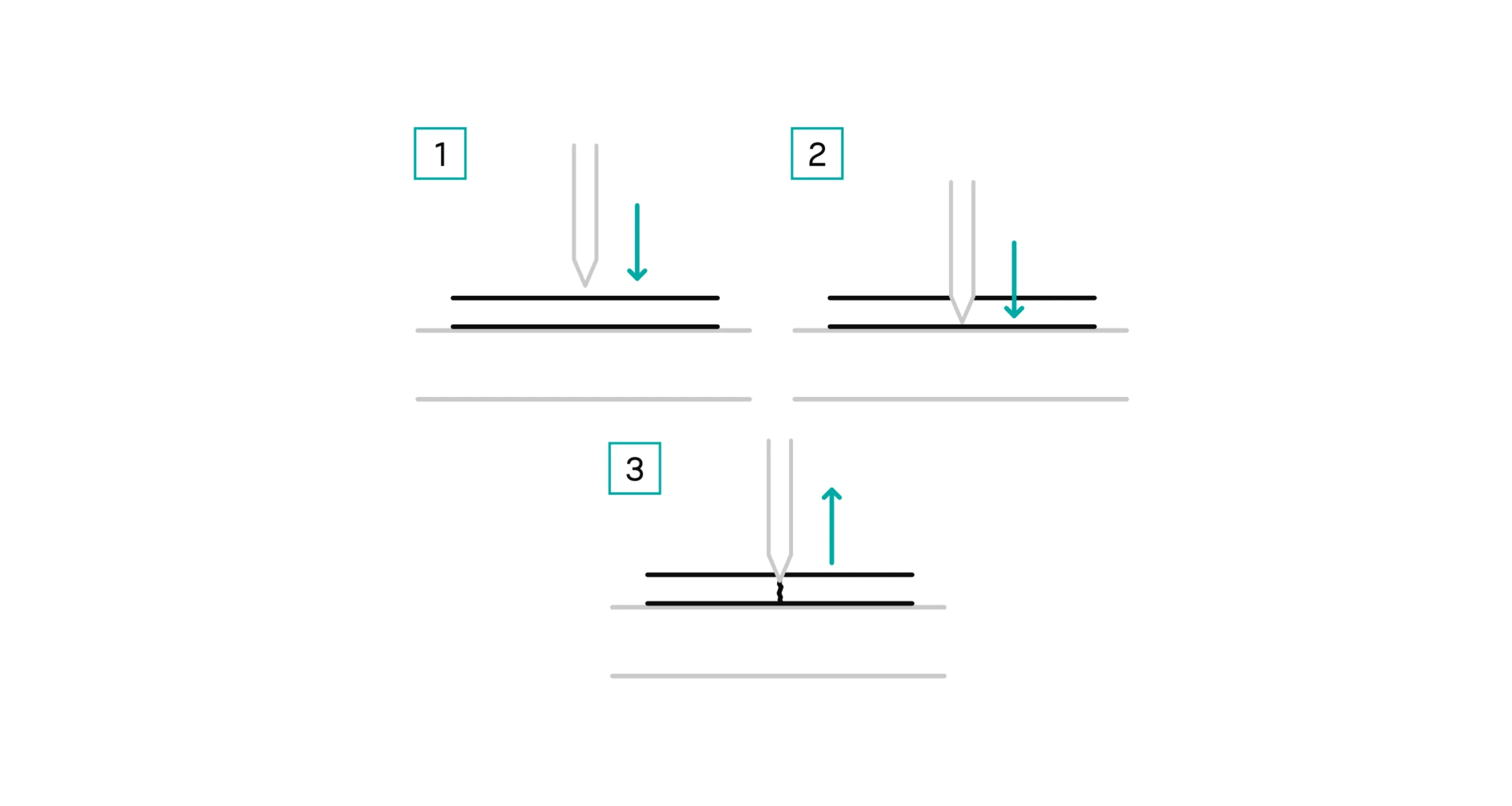

Once a thermoformed part has cooled, it must be separated from the tool and any excess material removed. Band steel cutting is a punching process used for trimming. It belongs to the blade cutting category, as a cutting wedge penetrates the defined contour of the thermoformed part. The punching tool consists of a band steel blade set in wood and a punching counterplate.

Capabilities & Characteristics of Band Steel Cutting

| Feature for Band Steel Cutting | Specification for Band Steel Cutting |

|---|---|

| Cutting Line | Cuts with predefined break points (interruptions) |

| Edge Quality | Breakpoint tabs may be noticeable |

| Visual Appearance | Breakpoint tabs may be visible |

| Max. Material Thickness | Up to 4 mm (Best quality up to 1.2 mm) |

| Cut Misalignment Risk | Dependent on roller quality and transport accuracy |

| Borderless Punching | Not possible – a minimum 0.5 mm punching edge is required to prevent wall penetration |

| Adjustable Cutting | Possible with band steel cutting |

| Heating Capability | Possible up to 200°C (punch and counterplate) |

| Processing Temperature | - Demolding temperature for thick materials - Room temperature for thin materials |

| Risk of Deformation (Stringing) | Avoidable with heated punching tools |

| Tool Lifespan | 50,000 – 200,000 cycles (depends on material, thickness, and tool design) |

Advantages & Disadvantages of Band Steel Cutting

- Low tooling costs

- Quick machine setup times

- Freeform areas remain unaffected by post-processing

- Ideal for small production batches

- Longer production times due to separate punching station

- Shorter tool lifespan (100,000–200,000 cuts)

- More precise trimming achievable with combined forming-punching tools

Frequently asked questions about strip steel cutting

When is strip steel cutting most suitable?

Strip steel cutting is suitable for small to medium quantities where low tooling costs and short delivery times are more important than maximum cutting precision.

Alternative Cutting Methods for Thermoformed Parts

Looking for other cutting methods beyond band steel cutting? We provide insights into alternative processes, including CNC milling and shear cutting.