Shear cutting overview

- Process: Die cutting with male and female dies

- Typical application: Series production with high quantities and tight tolerances

- Cutting quality: Very clean, no retaining bars or predetermined breaking points visible

- Advantages: Long tool life, tight tolerances, edge-free punching

- Restrictions: Higher tool costs, longer set-up times

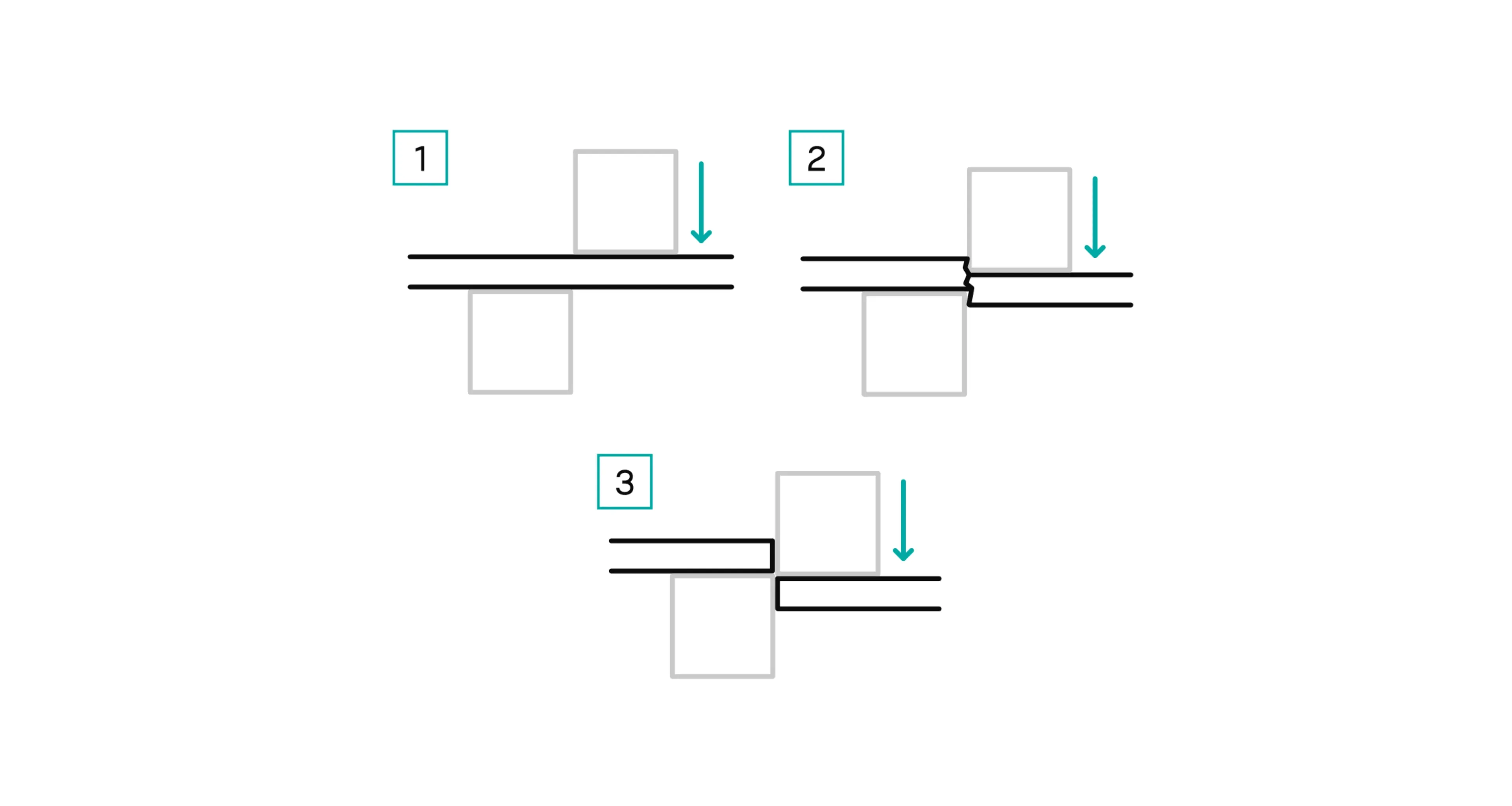

How Does the Shear Cutting Process Work?

Shear cutting is a precision manufacturing process where a punch and die move toward each other, creating a clean break at the cutting edge. This technique, known as drop-through cutting, is a key method for separating thermoformed plastic parts from their tooling while efficiently removing excess material. Alongside steel rule cutting, shear cutting is an excellent choice for achieving high-quality results with fast cycle times and precise cutting tolerances.

Shear Cutting with Drop-Through Cutting: Features & Capabilities

| Features & technical capabilites Shear Cutting | Specifications Shear Cutting |

|---|---|

| Cut Line | Continuous cuts along punch and die |

| Edge Quality | No hold tabs between parts and scrap grid |

| Visual Appearance | No visible holding tabs |

| Maximum Material Thickness | Up to 6 mm (optimal quality up to 1.2 mm) |

| Cutting Misalignment Risk | Depends on roller quality and transport precision |

| Edge-to-Edge Cutting | Seamless cutting possible |

| Adjustable Cutting | Feasible before mass production; tool must be fixed before series start |

| Heating Capability | Not possible with drop-through shear cutting |

| Material Stamping Temperature | - Demolding temperature for thick materials - Room temperature for thin materials |

| Deformation Risk (Stringing) | Always a potential risk |

| Tool Durability | 1 to 8 million cycles, depending on material, thickness, and tool design |

Shear Cutting: Pros & Cons

- Long tool lifespan

- Smooth cut edges

- Fast cycle times

- Ideal for high production volumes

- Higher tooling costs compared to other cutting techniques

- Longer setup times than steel rule cutting

Frequently asked questions about shear cutting

Is borderless punching really possible?

Yes. Unlike strip steel cutting, no safety margin is required.

Alternative Cutting Methods for Thermoformed Plastic Parts

Looking for other cutting techniques beyond shear cutting? Discover more about additional options such as CNC millingand steel rule die cutting.